Beer or similar alcoholic drink (e.g. cider) can be made from anything that contains starch, which is degraded by enzymes to simple sugars during the brewing process. If you consider sources of starch readily available in nature, chestnut is a viable option. It grows in forests all over the temperate climate in the Northern Hemisphere and is fairly easy to harvest in great quantities. The only thing you do is to pick it up. So I decided to make some chestnut beer.

Chestnut beer procedure

Firstly I tried to activate the enzymes in the chestnut to break down the starch. This would be analogous to turning barley into malted barley in regular beer production. It turns out it is not as simple as with barley. Both my attempts ended in moldy chestnut, with no visible signs of germination.

Since I already had my share of experience with malting barley, this was an unexpected disappointment. After some search on the internet, I learned that bringing chestnut to germinate is not as straightforward as with barley. It apparently consists of conditioning the seeds for several months.

My other beer related experiments:

This is definitely too complicated and the results are still not guaranteed. Therefore I decided for the approach used in wheat beer: adding malted barley. Enzymes in the malted barley break down all starch, regardless of the source and I guessed they will also work with chestnut starch.

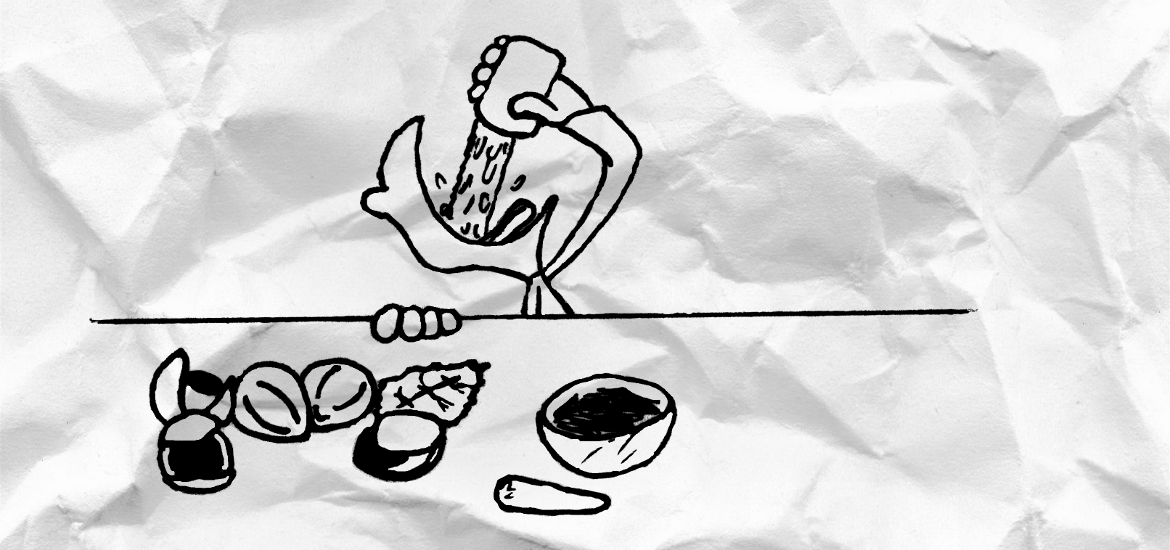

With the starting ideas for beer brewing set, I moved on to actually making chestnut beer. First, the chestnut was prepared. For the sake of taste, some baked chestnuts were added to the cooked ones, since I really like their taste. Nevertheless, the majority of the chestnut was cooked due to the fact that it is much easier to prepare them this way.

The most important thing in both cases is to completely remove the inner soft skin, which is sometimes tightly cowering the seed. It contains a lot of tannins and can give a bitter and acrid taste to the beer.

Hint: you can also buy cooked and expertly peeled seeds in the shop – this is by far the easiest option.

Next, I added malted barley to the chestnuts, poured the water over the mixture and started to heat up.

The same heating profile as with the wartime beer was used, only the time was slightly prolonged. I was not sure how effective the barley enzymes would be on chestnut starch, therefore I gave them some more time. After the heating steps were finished, solid parts were removed and I started the rolling boil.

Surprisingly there were not a lot of fine solids from the chestnuts, the worth looked as the one prepared from barley. Half of the hops were added at the beginning and the other half at the end to get some more flavor, not just the bitterness. After it cooled down the hops were removed and the yeast added.

Chestnut beer: was it any good? No.

The fermentation finished relatively fast – in three days. After four more days of standing, I primed the beer and filled it in bottles. The first Chestnut beer testing was done after one week of maturing. A disaster – there was practically no foam, and even worse, no taste. There was evidently too little hops but the most striking was the flat body.

Apparently, all carbohydrates were fermented and there was absolutely no substantial body to speak of. The heating profile was definitely wrong. Instead of giving the enzymes more time, as I did, the time should be shortened, to leave some carbohydrates for sweetness and fullness.

The first Chestnut beer try was a miss, but I got some good pointers for the next one, which should be a substantial improvement from this fiasco.

Image credit: Amazing food